Pallet Racking System

Pallet Racking System - Storage Solutions

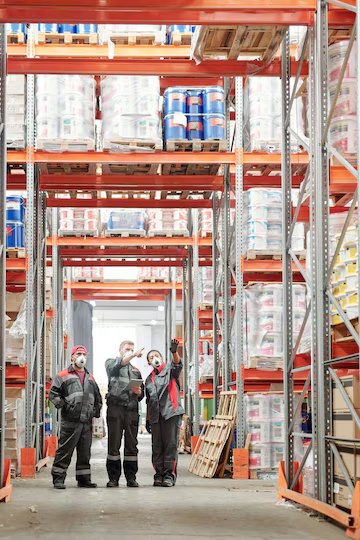

Pallet racking System is like shelves for pallets in a warehouse. It has vertical frames, horizontal beams, and wire decking to make levels for storage. This racking solution system saves space and makes warehouses work better. Warehouse racking types offer unique benefits. Selective racking allows easy access. Drive In racking maximizes space by driving into the rack. Push back racking offers dense storage with a Last In First Out system. Picking the right racking is key for staying organized and efficient. Different types suit different needs.

Pallet Racking System - Storage Solutions

Pallet racking System is like shelves for pallets in a warehouse. It has vertical frames, horizontal beams, and wire decking to make levels for storage. This racking solution system saves space and makes warehouses work better. Warehouse racking types offer unique benefits. Selective racking allows easy access. Drive In racking maximizes space by driving into the rack. Push back racking offers dense storage with a Last In First Out system. Picking the right racking is key for staying organized and efficient. Different types suit different needs.

Selective Racking

Selective racking and double deep racking are the most common types of pallet storage methods used in warehouses. Selective racking offers direct access to each and every pallets. This system lets forklifts grab or put pallets without shifting others, perfect for places where getting to each pallet fast matters. Pallet racking system packs items in tight while keeping them easy to reach, so it works well for businesses with lots of different stuff that gets moved often.

Double Deep Racking

Double deep racking stores pallets two deep, one behind the other, providing higher storage density. Special forklifts with extended reach are needed to access the rear pallets. Double deep racking sacrifices some accessibility compared to standard selective racking but offers increased storage capacity. This makes Pallet racking system cost effective for warehouses with limited room. Both selective racking & double deep racking help businesses

Space wisely

Pallet racking system is like a tall, sturdy bookshelf. It helps businesses use their space wisely. Stacking goods high and saving money on extra storage buildings. These systems make it easy to keep things organized. They also make it safer for workers by keeping goods off the floor. Plus, they help workers find things quickly, like finding a favorite book, which makes the warehouse run smoother. Pallet racking system helps businesses keep up with changes in their inventory and make the most of their warehouse space.

Selective Racking

Selective racking and double deep racking are the most common types of pallet storage methods used in warehouses. Selective racking offers direct access to each and every pallets. This system lets forklifts grab or put pallets without shifting others, perfect for places where getting to each pallet fast matters. Pallet racking system packs items in tight while keeping them easy to reach, so it works well for businesses with lots of different stuff that gets moved often.

Double Deep Racking

Double deep racking stores pallets two deep, one behind the other, providing higher storage density. Special forklifts with extended reach are needed to access the rear pallets. Double deep racking sacrifices some accessibility compared to standard selective racking but offers increased storage capacity. This makes Pallet racking system cost effective for warehouses with limited room. Both selective racking & double deep racking help businesses

Space wisely

Pallet racking system is like a tall, sturdy bookshelf. It helps businesses use their space wisely. Stacking goods high and saving money on extra storage buildings. These systems make it easy to keep things organized. They also make it safer for workers by keeping goods off the floor. Plus, they help workers find things quickly, like finding a favorite book, which makes the warehouse run smoother. Pallet racking system helps businesses keep up with changes in their inventory and make the most of their warehouse space.

Features of Selective Racking

Complete Versatility: Selective pallet racking can be customized for different warehouse needs, handling various pallet types and systems without replacements.

Maximize Storage Space: While limited by height, selective racking efficiently uses warehouse space by stacking pallets safely on top of each other.

Easy Inventory Access: This system allows easy access to all pallets, letting multiple forklifts operate in the same aisle for quick inventory movement.

First In First Out: Selective racking supports FIFO inventory management, ensuring stock is moved in the order it was received, beneficial for managing large quantities of products or SKUs with small stock amounts.

Cost Effectiveness: Selective pallet racking is affordable, with low material costs and minimal labor needed for installation. It can accommodate various handling systems without major changes post-installation.

Features of Double Deep Racking

Increased Storage Capacity: Double deep racking stores pallets two rows deep, doubling the stored pallets compared to standard racks within the same space.

Space Efficiency: Requiring fewer aisles to access loads, double deep racking saves space and enhances storage density, suitable for high-throughput operations.

Cost-Effective Storage Solution: Despite its increased storage capacity, double deep racking remains cost-effective due to its efficient floor space use and increased storage density.

Productivity Enhancement: This system enhances productivity by maximizing floor space utilization and providing higher storage capacity within a given area, ideal for warehouses with high inventory turnover rates.

OUR PRODUCTS

our latest products

Pallet racking systems provide an efficient storage solution by stacking pallets vertically.